Growing up attending Space Camp and Space Academy it was always a dream to become an astronaut. While the dreams of going to space have not been achieved yet, I was able to become an engineer who has worked on projects related to the space launches. So, when offered the chance to visit the NASA facility near New Orleans before the Super Bowl, I jumped at the chance.

We had the privilege of being invited to visit NASA’s Michoud Assembly Facility in New Orleans ahead of Super Bowl LIX for an inside look at the rocket factory and interviews with agency experts. The Michoud facility manufactures and produces large-scale space structures that carry astronauts and supplies to the Moon as part of the Artemis campaign, a lunar exploration program. The building spans a whopping 43 acres — or just over 31 professional football fields. The site generates 3000 jobs and has an economic impact of 17 million dollars each year.

Our exclusive tour was led by Chandler Scheuermann, a NASA engineer. We started in the Model Room where the early history of the manufacturing facility that pre-dated NASA was brought to light. The building originally functioned as a factory to produce cargo planes for WW2. NASA bought the building because of logistics with the nearby river and massive size of the location.

Since its beginnings, NASA has had an ongoing mission to bring younger generations into STEM and foster an environment and education for future solar system explorers. Composed of performance activities, evaluation activities, and a learning agenda, their STEM program aids in NASA’s mission of scientific discovery and technological development. Despite its limited access, Michoud welcomes students and school organizations, educating them on space launch systems production, factory operations, and the higher educational institutions Michoud partners with.

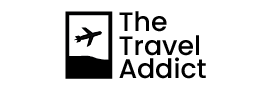

Next, we got to check out hardware being created for the space launch system (SLS.) The system is integral to NASA and their deep space exploration and the Artemis program. The current SLS is the only rocket that can send the Orion spacecraft, four astronauts, and cargo directly to the Moon in a single launch. Core stages, the 212 feet in diameter and 27.6 feet tall tanks that store 733,000 gallons of liquid hydrogen and liquid oxygen that power the RS-25 engines, are made here at NASA Michoud.

The SLS project is overseen by Hansel Gill, the subsystem manager for manufacturing and production for the exploration upper stage. State-of-the-art manufacturing equipment is used to make these special energy store-houses including a friction stir welding tool, the largest of its kind in the world. Propulsion systems and crew modules are built here as well.

The facility has on-site partners with Boeing, an aircraft company, and Lockheed Martin, an aerospace and defense company. Jerry Webber is the on-site Boeing tenant and Tim Livingston is the Lockheed Martin tenant. NASA also has tenants with the US Coast Guard and the USDA.

During a live Q&A session, Livingston told the media that Lockheed Martin is working on the crew module and external pieces of the Orion aircraft that will withstand 10,0000 degrees Fahrenheit with heat shields that will be finished at the Kennedy Space Center.

Boeing tenant Webber talked about the rigorous welding training program housed at NASA NOLA. For 18 months, trainees are supervised and partner with NASA experts to create the safest and most precise welds. When asked about the biggest changes made between the Apollo missions and Artemis, Lockheed Martin’s Livingston said that Artemis will house a fully functioning launch board and will be much bigger than the Apollo. The Artemis missions will also feature life support system upgrades and zero-weld defects based on continuous improvement efforts.

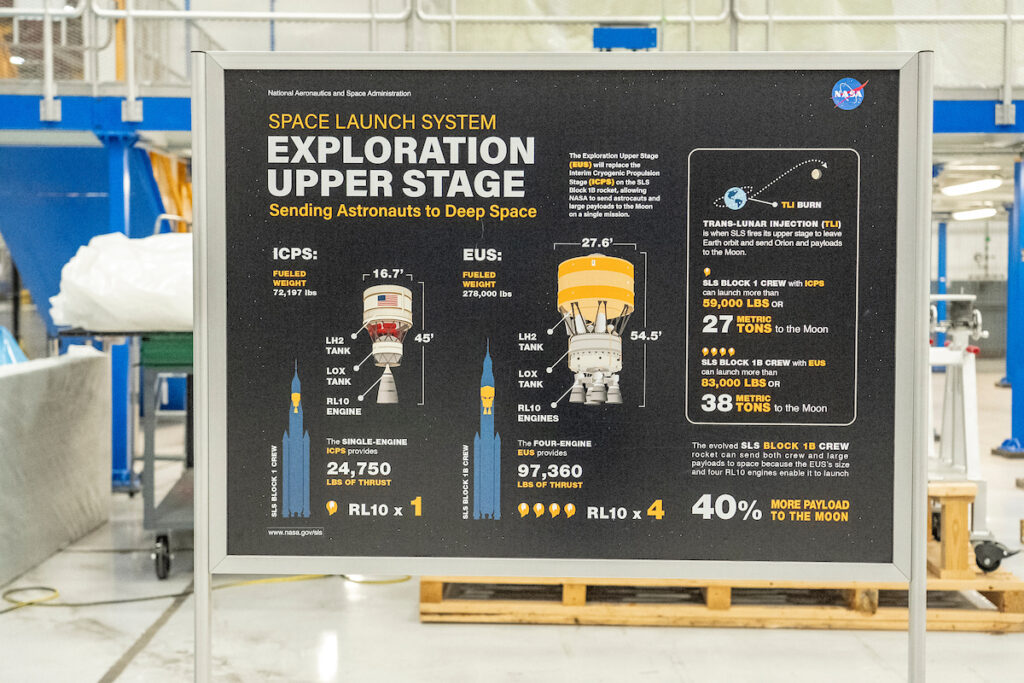

The initial propelling power for the Orion aircraft for the first three Artemis missions is from the interim cryogenic propulsion stage (ICPS.) For the building of Artemis four, the ICPS will be replaced by the exploration upper stage under contract to Boeing. The new system will produce four times more thrust power than the previous propellers.

Life Cycle of Artemis Missions

Artemis 1 – No crew flight test of the Space Launch System and the Orion spacecraft around the Moon in 2022.

Artemis 2 – First crewed flight test of the Space Launch System and the Orion spacecraft around the Moon scheduled for Spring 2026.

Artemis 3 – First humans to explore the region near the lunar South Pole for the first time since 1972 scheduled for mid-2027.

Artemis 4 – First lunar space station, a more powerful version of the SLS rocket, and new mobile launcher.

The long-term goal of the Artemis project and missions is to eventually have a human presence on Mars. In order to complete such a feat, the Mars rocket will have to be multiple times bigger than any Artemis rockets to be able to launch. It is known by scientists that Mars is one of the only other planets where life may have existed in the solar system. NASA believes that what we learn on Mars will tell us more about Earth’s past and future, and may help answer one of the universe’s big questions; Can life exist beyond Earth?